- Key Features

- Applications

- Available Options

-

01

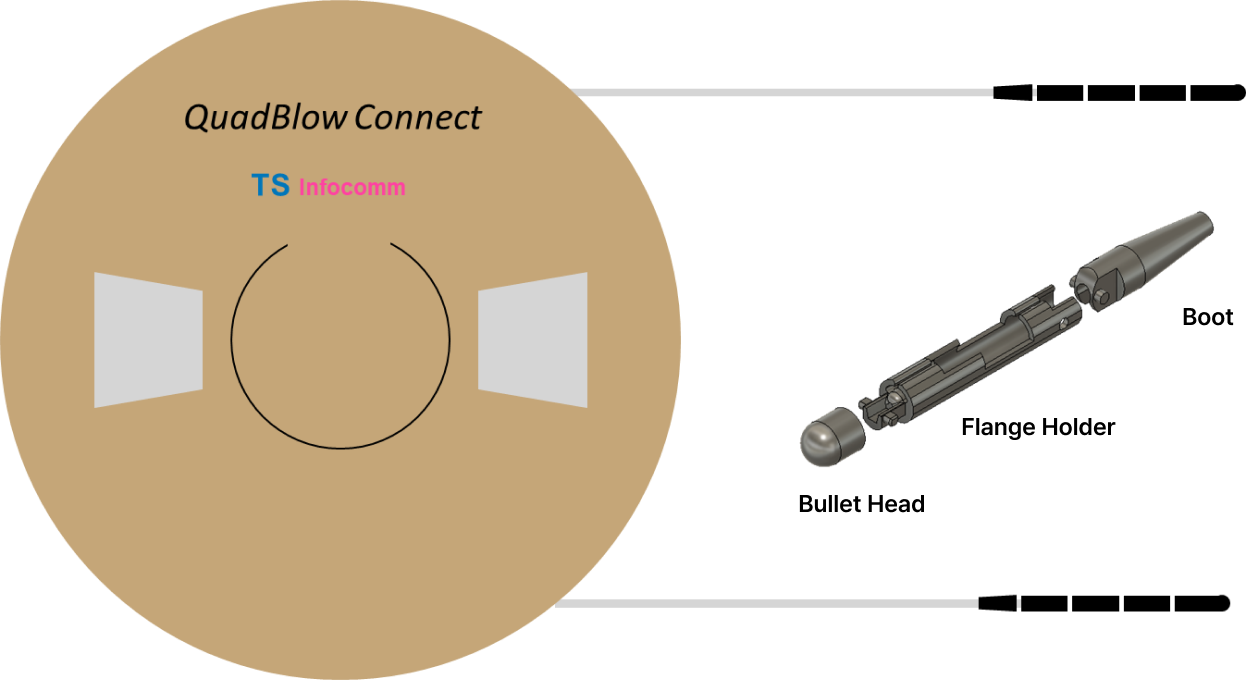

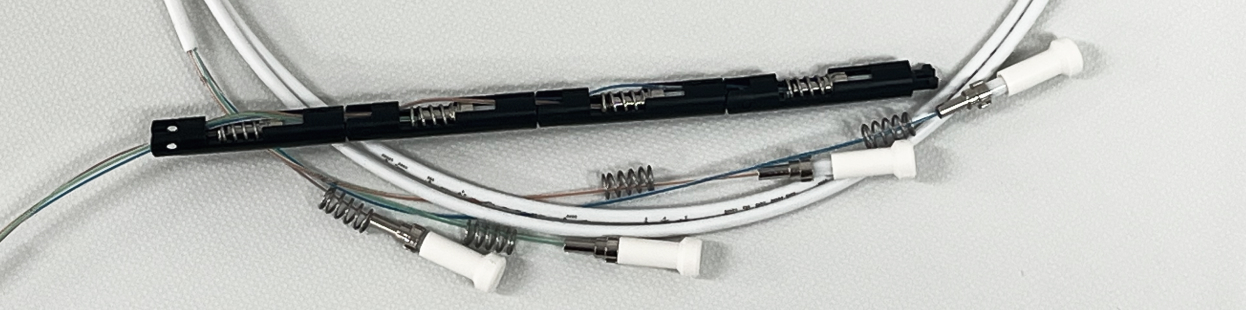

Multi-Core Cable Assembly

Features a termination assembly that allows each ferrule housing to bend laterally by 10 degrees, enabling smooth passage through 180-degree microduct bends with minimal friction.

-

02

Fast, Seamless Installation

The rounded blowing head minimizes resistance, ensuring rapid and efficient cable deployment without the need for on-site reassembly.

-

03

Enhanced Cable Protection

Ensures safe bending of fiber cables, maintaining optimal alignment and performance throughout the installation.

-

04

Modular Flexibility

The modular ferrule housing design supports serial connections, offering adaptability for diverse installation scenarios.

Ideal for FTTH, smart cities, and large-scale fiber optic networks, providing a high-performance, reliable solution for modern communication infrastructure.

| Microducts | Internal/External Installation - 7/10mm HDPE, 8/10mm HDPE |

|---|---|

| Fiber Counts | Up to 4 fibers |

| Fiber Types | Bend Insensitive Fibers - ITU-T G.657.A1, A2/B2, B3 |

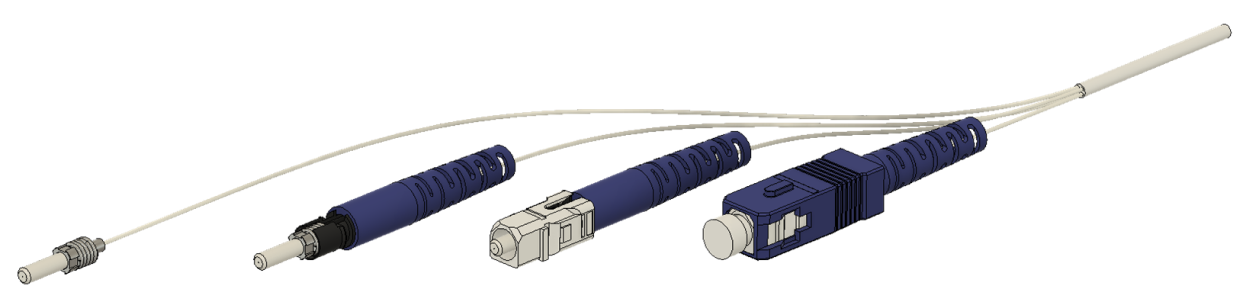

| Connector Types | SC/UPC, SC/APC |

| Fiber Lengths | 50m, 100m, 150m, 200m, 250m, 300m |

Optical Performance

| Process | Specifications (at 1310nm and 1550nm) | |

|---|---|---|

| Insertion Loss | Typ. | ≤0.15dB |

| Max. | ≤0.30dB | |

| Return Loss | Min. | >55dB (UPC), >65dB (APC) |

Fiber Types

| Item | Specifications |

|---|---|

| Applicable Fiber | Singlemode Fiber: ITU-T Rec. G.657, Diameter: 250μm |

Temperature Range

| Item | Specifications |

|---|---|

| Storage Temperature | -40 ~ 80°C |

| Operational Temperature | -40 ~ 75°C |

Mechanical/Environmental Performance

| Test | Conformance | Method / Condition | Specifications |

|---|---|---|---|

| Mating Durability | IEC 61300-2-2 / GR-326-CORE, 4.4.3.8 | No. of cycles: 200 | Loss Increase ≤ 0.3dB Return Loss Decrease ≤ 5dB |

| Vibration | IEC 61300-2-1 / GR-326-CORE, 4.4.3.1 |

Freq. Range: 10Hz ~ 55Hz Duration: 2h/axis for 3 axis Sweep rate: 1 octave/min Amplitude: 1.5mm |

Loss Increase ≤ 0.3dB Return Loss Decrease ≤ 5dB |

| Impact | IEC 61300-2-12 / GR-326-CORE, 4.4.3.7 |

8 drops 1.5m drop height |

Loss Increase ≤ 0.3dB Return Loss Decrease ≤ 5dB |

| Thermal Cycle | GR-326-CORE, 4.4.2.2 | -40°C±2°C to 75°C±2°C, 21 cycles, Dwell time: 1 hr at 23°C±2°C, Transition time: 1 hr | Loss Increase ≤ 0.3dB Return Loss Decrease ≤ 5dB |